ABOUT US

As Aliş Makina, we have been operating in Bursa since 1963. We design and implement engineering projects for various brands ranging from different sectors who are engaged in manufacturing in Turkey and around the world. We specialize in designing the best products in different manufacturing areas such as conveyor, sorter, and thermo drive systems, as well as custom machine manufacturing and line solutions. We strive to deliver our products to the satisfaction of our customers.

We design our projects in accordance with occupational safety rules in order to make the production line efficient. At the beginning of each project, we carefully listen to our customer’s expectations and needs, and conduct on-site analysis. Next, together with our product development team, we create the most suitable project design for the production area. Whilst the working process, we continue to address our customers’ questions and suggestions. After conducting tests and performing the final checks, we also provide after-sales and technical support services once the project is finalized.

We started off with lathe manufacturing in the automotive sector and gradually expanded our production area to work on conveyor systems. We resume to grow with the projects we have developed to serve the food sector. As the third generation, we protect the heritage that the previous two generations have passed on to us, together with their knowledge and experience. Along with this heritage, we have inherited the values of dedication, reliability, and honesty. Therefore, we work with the principles of being meticulous and are solution-oriented in the projects we specially prepare for our customers, who are among the leading brands of Turkey and the world.

History

Vision

Mission

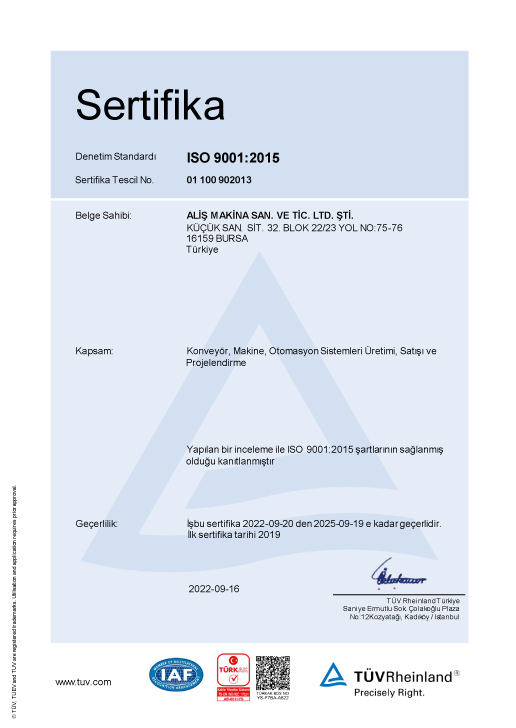

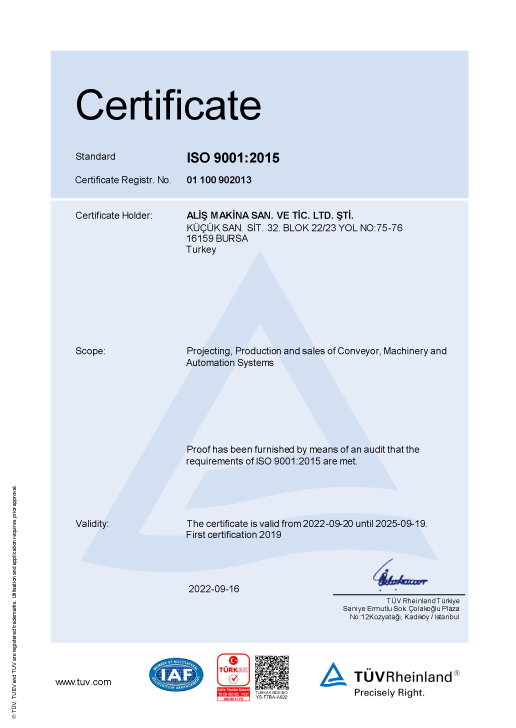

Quality Policy

As Aliş Makina, which carries out sales and project design activities in the fields of conveyor, machine manufacturing and line solutions, we have a quality management system that is suitable for the purpose and context of our company and supports its strategic direction. The following policies are implemented in order to keep the quality management at the highest level in our projects and services.

- To understand and analyze the needs and expectations correctly in order to ensure internal and external customer satisfaction.

- To adopt customer-oriented work based on quality in production and service.

- To establish cooperation with suppliers based on trust and mutual benefit.

- ISO 9001:2015 Quality Management System and to continuously improve the system.

Career

You can view open positions on our Kariyer.net page and apply for a job, or you can follow our company to be notified about new job postings.

You can send your resume to the email address alis@alismakina.com.tr indicating the specified position you wish to apply for.

References