Introduction: Why is the Right Tape Material Critical?

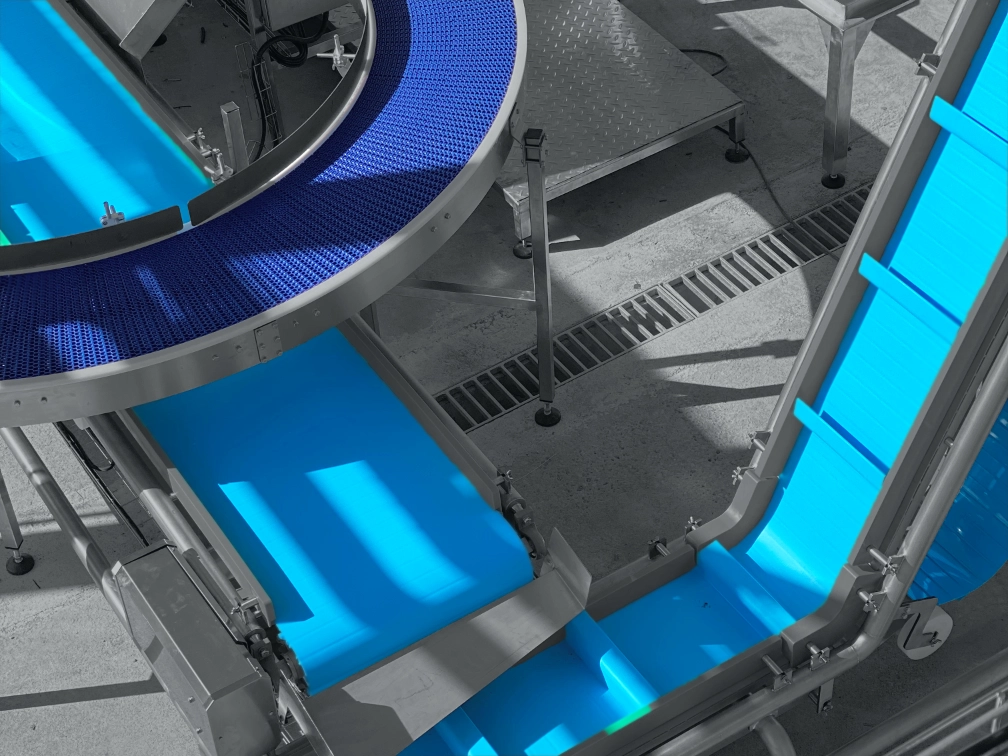

Modular plastic belt conveyors do more than just transport goods on production lines. Line continuity, product stability, hygiene levels and maintenance intervals are directly dependent on the belt material. Therefore, selecting the right plastic material for modular conveyor systems is one of the key factors determining overall system performance.

The belt material must be evaluated in conjunction with parameters such as line speed, product weight, ambient temperature, cleaning method and chemical exposure. Incorrect selection leads to premature wear, product imbalance and unplanned downtime.

Aliş Makina determines the modular belt material according to line conditions by addressing each application on a process-based basis.

Basic Plastic Materials Used in Modular Conveyors

Modular conveyor belts consist of injection-moulded thermoplastic modules. The most commonly used materials in these systems are PP, PE and POM. Each offers different mechanical and environmental advantages.

Polipropilen (PP)

It is a lightweight and economical material. It has high chemical resistance and works efficiently under low to medium loads.

Typical areas of use:

Dry food lines, packaged goods transport, secondary packaging and light load applications.

Polietilen (PE)

It retains its flexibility at low temperatures and has high impact resistance. Its smooth surface ensures low product friction.

Typical areas of use:

Cold environments, frozen food transfer, damp and wet processes.

Acetal (POM)

It offers high mechanical strength and a low coefficient of friction. Thanks to its dimensional stability, it operates reliably at high speeds.

Typical areas of use:

Beverage lines, bottle and can handling, high-speed filling and directing systems.

Note: PU and ThermoDrive belts are not modular plastic belts.

PU belts are single-piece hygienic belts, while ThermoDrive is a special monolithic, positively driven belt technology. They are not classified in the same category as modular belts.

Technical Performance Based on Material Properties

Mechanical Strength

POM modular belts offer stable performance over long distances and at high speeds thanks to their high tensile strength.

PP tapes, on the other hand, reduce energy consumption due to their low weight.

Temperature Resistance

PE tapes operate without the risk of cracking at low temperatures.

POM tapes maintain their dimensional stability in medium temperature ranges and are preferred in hot filling lines.

Chemical Resistance and Cleaning

PP and PE can be safely used in lines where concentrated detergents and chemicals are used.

Open-area modular belt geometries facilitate drainage, reducing cleaning times.

Noise and Flow Stability

POM strips operate with low vibration even at high speeds.

The risk of product tipping and jamming is reduced with the correct module geometry and line design.

Selecting the Correct Tape for the Application

The selection of modular belt material should be made by jointly evaluating the product type and process conditions.

•Beverage bottle and can lines: POM

•Dry food and packaged products: PP

•Cold and damp environments: PE

•Direct contact lines requiring high hygiene standards: PU or ThermoDrive systems instead of modular belts

This approach extends belt life while maintaining line efficiency.

Aliş Makina's Engineering Approach

For Aliş Makina, selecting the belt material alone is not sufficient. The material must be considered in conjunction with the correct module type, correct line geometry and appropriate speed profile.

Each project is evaluated using the following steps:

•Analysis of product and process conditions

•Determining the appropriate modular belt material

•Optimisation of route layout and transition points

•Production and testing processes compliant with CE standards

This approach enables the design of long-lasting and stable conveyor systems.

Conclusion: Tape Material Selection is a Design Decision

The selection of modular conveyor belt material is a critical decision not only in terms of mechanical strength, but also in terms of production continuity, cleaning efficiency and total cost of ownership.

With the right material:

•Unplanned stoppages decrease

•Maintenance periods are reduced

•Industrial conveyor lines operate more stably

The Aliş Makina engineering team determines the most suitable modular belt solution for each line based on the process.

Determine the Right Belt Material for Your Production Line

Increase efficiency in your modular conveyor system with the right belt material.

Let Aliş Makina design the process for you with bespoke engineering solutions tailored to your application.